Shop by Category

Milling & Metalworking Demo Videos

Please select from the categories below to view available videos.

Subscribe to our YouTube Channel to be notified of new video releases!

We also offer a library of free milling training videos.

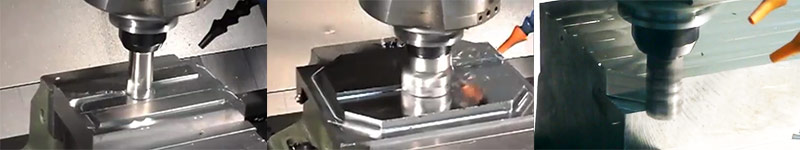

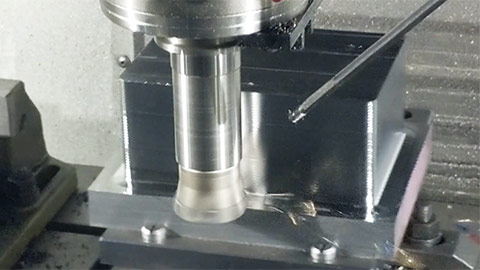

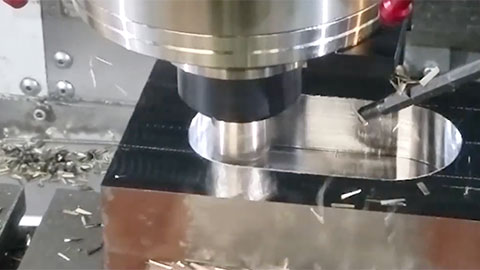

Long-Reach Profile Milling

Constant ramping with a 90-degree shoulder mill is a great technique for easy, efficient long-reach profiling with good surface finishes – even in the roughing cut.

Check out this demo for a peek at this approach using an EDGE² DSS series shell mill.

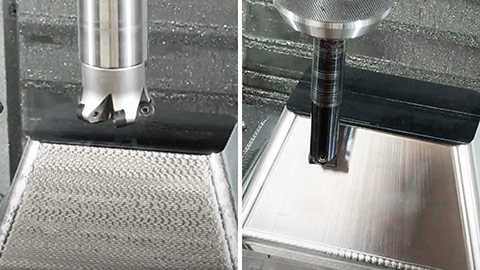

3D Milling Tips

3D milling involves a variety of tools and tool paths. In less than 5 minutes, this video demonstrates three different 3D shapes, what tools DAPRA recommends for machining and some suggestions for tool path generation for each.

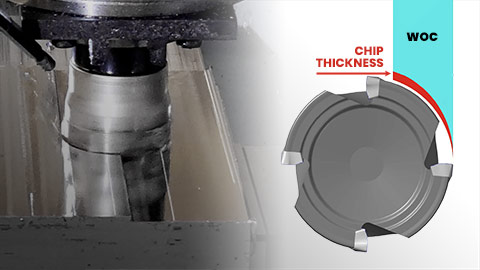

Radial Chip Thinning to Maximize Feed Rate

If you’re milling at less than 50% of your cutting tool diameter, you can minimize your cycle time – and maximize productivity – by properly adjusting your programmed feed per tooth.

Deep, High-Feed Ramping Beats High-Efficiency Milling

This quick contour milling demo illustrates how you can match the metal removal rates of high-efficiency milling with a solid carbide end mill – and save significant money on tooling – by ramping with an indexable high-feed tool.

Check out the advantages of high-feed ramping over high-efficiency milling.

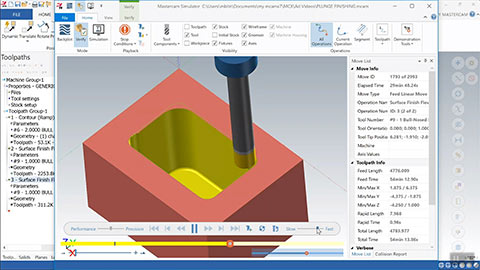

High-Feed Ramp with a Button Cutter, Plunge Finish with Bull Nose

In this detailed instructional video (16 min 45 sec), we look at some unexpectedly efficient options for mold core roughing and finishing.

Have you considered that a button cutter might actually be a great choice for high-feed mold core ramping? We also compare options for finishing the part, comparing bull nose to ball nose cutters and waterline profiling to plunge finishing.

Check out these interesting methods for ramping up your profitability.

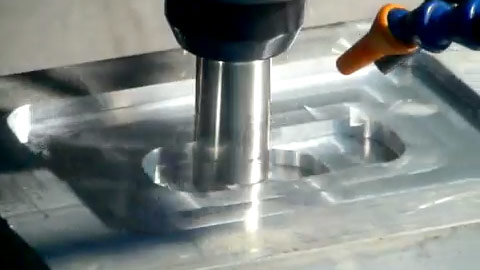

Roughing & Finishing a Mold Insert Chase Pocket

A solid approach to quickly and accurately milling a deep chase pocket can be a big money-maker for mold shops. Here, we look at a good option for roughing, semi-finishing and finishing the walls and floor of a deep, straight-walled mold insert pocket.

Check out a detailed instructional video or just the live cutting footage.

High-Feed Ramping for Outside Profile Contour Milling

Detailed instructional video (11 min 14 sec) comparing three methods for outside profile contour milling. See how to program each method, compare cycle times, and view demo footage of high-feed ramping on a Haas 40-taper VM2.

- Traditional 2D step-down milling

- High-efficiency/dynamic milling with a solid carbide end mill

- High-feed ramping with an indexable milling tool

Roughing Comparison: High-Feed Ramping vs. High-Efficiency Milling

Detailed instructional video (15 min 42 sec) comparing high-feed ramping to high-efficiency/dynamic milling in a typical pocketing application.

Dynamic milling may be all the rage right now, but in many cases high-feed ramping with an indexable milling tool can be a more efficient and flexible solution.

Check out the comparison, including both a high-feed end mill and shell mill.

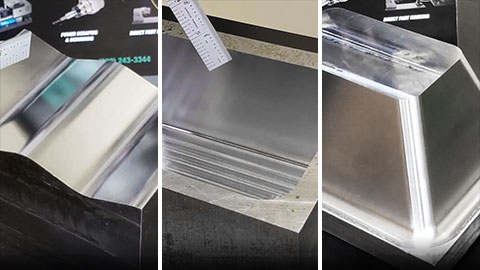

High-Feed Ramping & Plunge Finishing for 30-50% Cycle Time Reduction on Tapered or Deep Walls

This detailed instructional video (16 min 32 sec) shows you how to take advantage of plunge finishing utilizing the diameter of a tool, rather than the corner radius of a tool, to dictate the stepover needed to achieve a certain scallop height. By using plunge finishing, you can save 30% to 50% of the cycle time thanks to much larger stepovers.

Check out this simple, effective approach to finishing tapered walls and deep, straight walls.

High-Efficiency Milling vs. High-Feed Contour Ramping

Compare cycle time and tooling cost for three approaches to machining a 1" deep x 3.5" wide x 6" long pocket in 4140PH (28 Rc):

- High-efficiency milling – 1/2" solid carbide end mill

- Double-pass high-feed ramping – 1" indexable end mill

- Single-pass high-feed ramping – 2" indexable end mill

High-Efficiency Milling of 6061 ALU with Helical Roughing End Mills

Dynamic/volume milling with indexable tooling rather than solid carbide end mills.

- 3/4" dia. Helical Roughing End Mill

- 6061 aluminum

- Pocketing routine

- .900" depth

- Total cycle time: 5 min. 30 sec.

Dynamic Milling 1018 Steel with Helical Roughing End Mills

Indexable helical roughing end mills are a great alternative for dynamic/volume milling.

- 3/4" dia. Helical Roughing End Mill

- 1018 steel block

- Pocket & outside contour

- .850" depth

- Total cycle time: 4 min. 17 sec.

Profile Milling: Constant Profile Ramping vs. Standard Z-Level Profiling

Constant profile ramping is a much more effective approach than conventional Z-level profiling. Watch side-by-side as a Dapra 1” end mill (50 IPM / .100" DOC) using constant ramp profile outpaces a traditional 1° helix entry and Z-level rough by more than 50%.

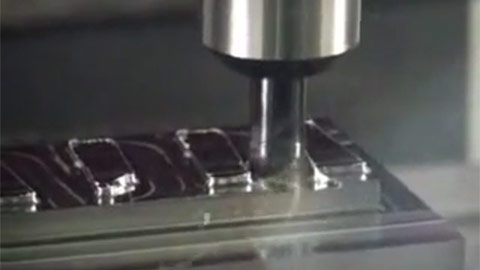

Dynamic Milling / Volume Milling Demo - Helical Roughing End Mill

- 1" diameter Helical Roughing End Mill

- 1018 steel – 6.13" x 4.0" block

- 1” deep pocket and profile

Plunge Milling Demo

- 2” diameter SSPM-series shell mill

- 5-flute

- 1018 steel, 4” wide, 4” deep

- Total cycle time: 3.2 minutes

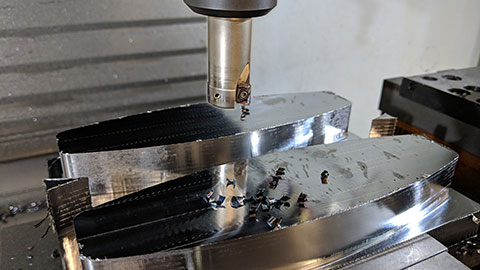

DSS Double-Sided Square Shoulder Series

The new EDGE² DSS line provides premium performance, free cutter replacement and cost-per-corner savings of up to 48% to revolutionize the way your shop approaches 90° milling. This demo shows:

- Profile milling 4140PH material

- Profile milling 1018 open contour and ramp milling 1018 pocket

- Face milling 304 stainless steel

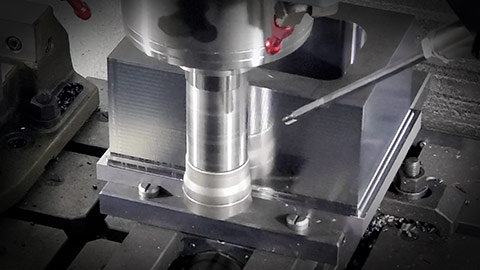

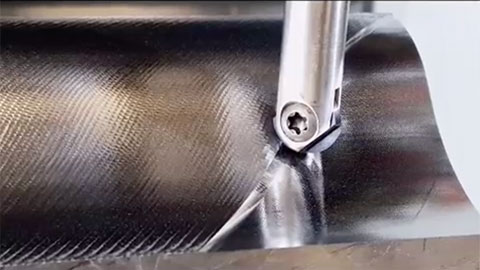

SBD Back Draft Finishing Inserts for SBN Series Cutters

New SBD back draft-style finishing inserts feature a positive-rake side-cutting wiper, an ultra-robust carbide insert, and a unique and rigid insert mount for maximum performance in long-reach, low-pressure finishing cutting. This demo shows these inserts performing the following at 6700 RPM / 200 IPM:

- Constant-ramp profiling on an inside pocket and outside profile

- Plunge finishing on a tapered wall

SBN Series Spherical Ball Nose

.030" semi-finishing demo:

- 3/4" diameter SBN

- 8,000 RPM

- 210 IPM

.010” finishing pass demo :

- 1/2" diameter SBN

- 12,000 RPM

- 300 IPM

SBN Series Spherical Ball Nose Semi-Finishing 4140PH Steel

- 3/4" diameter SBN (SBN-0750)

- 10,000 RPM

- 350 IPM

- .030" DOC

- .030" WOC

DTB Series 2" Double-Sided Button Cutter Milling D2 Material

- Extended Holder (5.5")

- 600 SFM (1150 RPM)

- .050 DOC

- 230 IPM!!!

- (.040" FPT)

DTB Series 2" Double-Sided Button Cutter Helix Operation

- Helix operation

- 3.5" diameter

- Thru-hole

- 1.25" thick 4140PH

- 150 IPM

- .035" helix

1" Mini-Feed End Mill, 3-Flute Low-Carbon Steel Pocketing Routine

- 800 SFM (3000 RPM)

- .036" FPT (325 IPM)

- .030" DOC

- 50% WOC

High-Feed Shell Mill Cutting Inconel 718

- 2" Mid-Feed Shell Mill - 5 flute

- Inconel 718 material (41 HRC)

- 80 SFM (150 RPM)

- 23 IPM (.030" FPT)

- .030" DOC

- 60-100% WOC

- Coolant recommended

- (Aculube used for clarity)

High-Feed End Mill Pocketing Inconel 718

- 3/4" Mini-Feed End Mill - 2 flute

- Inconel 718 material (41 HRC)

- 88 SFM (450 RPM)

- 18 IPM (.020" FPT)

- .020" DOC

- 60-100% WOC

- Coolant recommended

- (Aculube used for clarity)

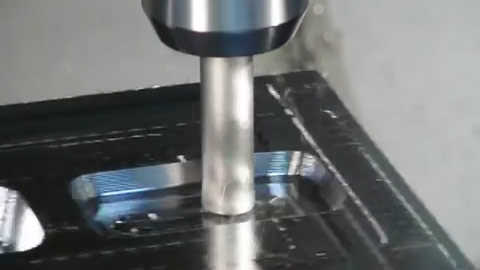

Milling H13 Extrusion Die Opening

- 1" dia. Extended Reach Tool (6.13" effective)

- Carbide core modular extension

- H13 material

- 810 SFM (3100 RPM)

- .039" FPT (240 IPM)

- .020" DOC

- 1.25" slot width

Milling 4140PH Steel with Mid-Feed End Mill - .035" DOC

- 1" Mid-Feed End Mill - 2 flute

- 4140PH steel material

- 600 SFM (2300 RPM)

- .050 FPT (230 IPM)

- .035" DOC

- 50% WOC

Milling 316L Stainless with Mini-Feed End Mill - .020" DOC

- 5/8" Mini-Feed End Mill - 1 flute

- 316L stainless steel material

- 450 SFM (2750 RPM)

- .031 FPT (85 IPM)

- .020" DOC

- 50% WOC

Milling 4140PH Steel with Mini-Feed End Mill - .020" DOC

- 5/8" Mini-Feed End Mill - 1 flute

- 4140PH steel material

- 700 SFM (4280 RPM)

- .035 FPT (150 IPM)

- .020" DOC

- 50% WOC

Milling 316L Stainless with Mid-Feed Shell Mill - .035" DOC

- 2" Mid-Feed Shell Mill - 5 flute

- 316L stainless steel material

- 350 SFM (670 RPM)

- .035 FPT (120 IPM)

- .035" DOC

- Variable WOC up to 100%

Milling 4140PH Steel with Mid-Feed Shell Mill - .035" DOC

- 2" Mid-Feed Shell Mill - 5 flute

- 4140PH steel material

- 550 SFM (1050 RPM)

- .055 FPT (300 IPM)

- .035" DOC

- Variable WOC up to 100%

Slotting with 3/4" Square Shoulder End Mill to 1/2" Depth

- 3/4" Square Shoulder End Mill

- 12mm XPET120408 inserts

- 1018 material

- 900 SFM (4600 RPM)

- 65 IPM on full slot (.007" FPT)

- 110 IPM on side cuts (.012" FPT)

- .165" DOC per pass

- 40 taper VMC

1" Square Shoulder End Mill Profiling Stainless Steel

- 1" Square Shoulder End Mill - 3 flute

- 12mm XPET120408 inserts

- 304L stainless steel

- 800 SFM (3050 RPM)

- 82 IPM (.009" FPT - 3 flutes)

- .100" DOC

- 40% to 100% WOC

- Run dry for clarity (MQL used)

- 40 taper VMC

2" Shell Mill Cutting 4140PH at .200" DOC

- 12mm APET120408 Inserts

- 40 taper VMC

- 700 SFM (1340 RPM)

- 55 IPM (.006" FPT - 7 flutes)

- .200" DOC

- 1" WOC (50%)

Helical Roughing Steel with a Square Shoulder End Mill

- 1" Helical Roughing End Mill

- APET1003 inserts

- 4140PH material (30 Rc)

- 700 SFM (2700 RPM)

- .0075" IPT (40 IPM)

- .750" DOC

- .100" WOC

- 40 Taper VMC

Slotting 1018 Steel with a Square Shoulder End Mill

- 3/4" Square Shoulder End Mill

- XPET1003 inserts

- 1018 low-carbon steel

- 1000 SFM (5000 RPM)

- .006" IPT (60 IPM) - full slot

- .010" IPT (90 IPM) - sides

- .075" DOC

- 40 taper VMC

90-degree Profiling Steel with a Square Shoulder End Mill

- 1" Square Shoulder End Mill

- APET1604 inserts

- 4140PH material (30 Rc)

- 700 SFM (2700 RPM)

- .012" IPT (65 IPM)

- Variable WOC

- .100" DOC

- 40 taper VMC

90-degree Pocketing Aluminum

- 1" Square Shoulder End Mill

- XPET1604-ALU inserts

- 6061 material

- 2000 SFM (7640 RPM)

- .026" IPT (400 IPM)

- .250" DOC

- .600" WOC

- 40 taper VMC

90-degree Helixing Aluminum

- 1" Square Shoulder End Mill

- XPET1604-ALU inserts

- 6061 aluminum material

- 1.75" diameter hole helical interpolation

- 2000 SFM (7640 RPM)

- .015" IPT (225 IPM)

- .030" helix

- 1.25" total depth

- 40 taper VMC

90-degree Face Milling Steel with a Square Shoulder Shell Mill

- 2" Square Shoulder Shell Mill

- APET1604 inserts

- 4140PH material (30 Rc)

- 700 SFM (1340 RPM)

- .012" IPT (80 IPM)

- .100" DOC

- 1.2" WOC (60%)

- 40 taper VMC

90-degree Face Milling Stainless Steel with a Square Shoulder Shell Mill

- 2" Square Shoulder Shell Mill

- XPET1604 inserts

- 316L stainless steel

- 550 SFM (1050 RPM)

- .012" IPT (63 IPM)

- .100" DOC

- 1.2" WOC (60%)

- 40 taper VMC

5/8" Square Shoulder End Mill

- 5/8" Square Shoulder End Mill

- 85 IPM

- .050" DOC

- 4140PH – 30 Rc

1" Square Shoulder End Mill

- 1" Square Shoulder End Mill

- 85 IPM

- .125" DOC

- 4140PH – 30 Rc

Toroid End Mill Pocketing Steel – .020" DOC

- 1" Toroid End Mill - 3 flute

- H13 material

- 700 SFM (2700 RPM)

- .030" IPT (243 IPM)

- .020" DOC

- 60% WOC

- 40 taper VMC

Pocketing Steel - .030" DOC

- 1" Toroid End Mill - 3 flute

- H13 material

- 700 SFM (2700 RPM)

- .022" IPT (180 IPM)

- .030" DOC

- 60% WOC

- 40 taper VMC

Toroid End Mill Helixing Steel - 150 IPM

- 1" Toroid End Mill (2 flute)

- 1018 low-carbon steel

- 1200 SFM (4600 RPM)

- .016" IPT (150 IPM)

- .030" helix

- 1.75" hole diameter

- 1.25" total depth

- 40 taper VMC

Helixing Steel - 188 IPM

- 1" Toroid End Mill (2 flute)

- 1018 low-carbon steel

- 1200 SFM (4600 RPM)

- .020" IPT (188 IPM)

- .030" helix

- 1.75" hole diameter

- 1.25" total depth

- 40 taper VMC

Helixing Steel - 225 IPM

- 1" Toroid End Mill (2 flute)

- 1018 low-carbon steel

- 1200 SFM (4600 RPM)

- .025" IPT (225 IPM)

- .030" helix

- 1.75" hole diameter

- 1.25" total depth

- 40 taper VMC

Toroid End Mill Pocketing Steel - .100" DOC

- 1" Toroid End Mill – 2 flute

- H13 material

- 700 SFM (2700 RPM)

- .020" IPT (108 IPM)

- .100" DOC

- 60% WOC

- 40 taper VMC

Toroid Shell Mill Face Milling with High-Feed Inserts

- 2" Toroid Shell Mill - 5 flute

- 4140PH material (30 Rc)

- 700 SFM (1340 RPM)

- .055" IPT (370 IPM)

- .030" DOC

- 1.2" WOC (60%)

- 40 taper VMC

Toroid Shell Mill Face Milling with Octagonal (8-sided) Inserts

- 2" Toroid Shell Mill - 5 flute

- 4140PH material (30 Rc)

- 700 SFM (1340 RPM)

- .012" IPT (80 IPM)

- .100" DOC

- 1.2" WOC (60%)

- 40 taper VMC

Toroid Shell Mill Face Milling with Button Inserts

- 2" Toroid Shell Mill - 5 flute

- 4140PH material (30 Rc)

- 700 SFM (1340 RPM)

- .030" IPT (200 IPM)

- .050" DOC

- 1.2" WOC (60%)

- 40 taper VMC

RDBN Rough-Duty Ball Nose Inserts

New RDBN inserts are designed for demanding light roughing and finishing applications. This demo shows RDBN inserts performing the following:

- Heavy 3D rough 1018 steel

- Semi-finish hardened H13 (50 Rc)

- Corner round 1018 low-carbon steel

1/2" Ball Nose End Mill Finish Cut

- 1/2" Ball Nose End Mill

- 375 IPM @ 16,000 RPM

- .010" finish cut

- 4140PH – 30 Rc

1/2" Ball Nose End Mill Finish Cut

- 1/2" Ball Nose End Mill

- 375 IPM @ 16,000 RPM

- .010" finish cut

- 4140PH – 30 Rc

3/4" Ball Nose End Mill

- 3/4" Ball Nose End Mill

- .030" DOC x .030" WOC

- 4140PH – 30 Rc

3/4" Ball Nose End Mill

- 3/4" Ball Nose End Mill

- .030" DOC x .030" WOC

- 4140PH – 30 Rc

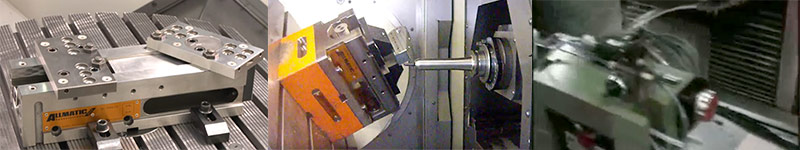

Servopress Indexing Table Demo

- Square block grinding accurate to .0002" over 11.25 inches

- Indexer Model: Servopress RSTH30-D250-PHI-Q1-V10-G72R

- Video courtesy of Applied Medical Resources, Rancho Santa Margarita, CA

DMWriter™ MX CNC Part Marking Demo

Dot peen marking solution for direct part marking in CNC milling machines.