Modular Assemblies vs. Solid Tooling

Carbide core extensions give your modular setups the strength to stand up to tough roughing applications

Modular tool systems offer outstanding flexibility to economically change between different applications and lengths of cut. But can they actually compete with solid tooling when it comes to delivering premium, dependable performance?

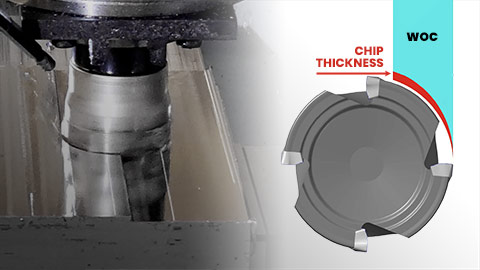

Here we put a modular assembly with a carbide core extension up against a comparable solid steel tool in this typical roughing application, eliminating corner rounding to apply maximum stress to the long-reach cutters. Same effective reach, number of flutes and tough mid-feed inserts. Same parameters and tool path. Here's how the two setups fared:

Conventional thought in manufacturing is that a solid tool is "better" due to more accurate concentricity. For strictly finishing work, this is often true. When roughing, however, rigidity is key. This side-by-side comparison shows what a difference our carbide core extensions can make.

Both tools handle the cut well, with minimal corner chatter. But, where the solid tool is dedicated to specific inserts and applications, the modular assembly can be switched out to many different style heads and extension lengths. With a modular assembly, the head can be replaced at roughly a 20-30% cost savings vs. a new solid tool. Dapra is the only tooling provider to offer carbide core modular extensions, and we've just expanded our selection with several shorter-length extensions that create medium overall-length setups.

Benefits of Dapra's modular systems

- Modular setups are more economical than dedicated solid tools, allowing multiple types of screw-on heads to be used

- We offer a carbide core in our standard modular extensions, providing enhanced rigidity over steel extensions

- When combined with a screw-on head, our short-length modular extensions create a typical medium overall-length tool

- All modular extensions and heads are compatible with industry ISO-standard modular systems

Trying to decide if a modular system makes sense for your shop?

Get more tech tips!

Join our email list or follow our social channels for regular tech tips. Need assistance with your application? Contact one of our technology specialists to review your parameters.

Choose the best indexable tooling the first time – every time

Choose the best indexable tooling the first time – every time Maximize feed rate with radial chip thinning

Maximize feed rate with radial chip thinning