Shop by Category

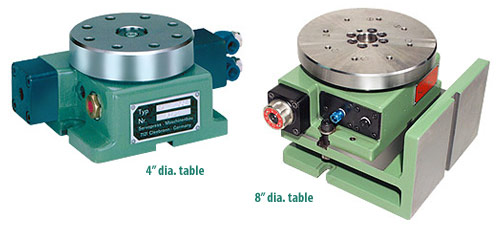

Servopress Automatic Indexing Tables

Precision rotary tables for assembly, machining and more.

Servopress Indexing Tables offer superior indexing accuracy and repeatability, extremely rapid index times for high-production applications, and precise locking with Hirth or Ball couplings. Drives are available in electric, pneumatic, hydraulic, or combination.

The potential applications for Servopress tables are endless. Indexing tables may be utilized in environments ranging from assembly to machining; from computer assembly, to printing, to special machinery builders. They are also great for square block grinding.

Design Features

The most unique feature of the Servopress design is the ability to assemble a table that is tailored to the customer's specific application. Among the many design options that these tables offer are:

- Standard sizes from 2" to 49" + diameter

- Choice of Accuracies: Standard ± 24 arc sec. to Q1 ( ± 1/2 arc sec.)

- Choice of Drive Systems: Pneumatic (for light loads); Pneumatic / Hydraulic (for medium loads); Hydraulic (for heavy loads)

- Choice of Control Systems: Pneumatic (simple interface); Electric (for more sophisticated interfaces) when used in conjunction with CNC controls

- Choice of Couplings: Ball coupling (highest precision / wear resistant); Hirth Gear Face coupling (for higher machining forces) – see diagram below

- Choice of Direction of Rotation: clockwise; counterclockwise; reciprocating

- Choice of Fixed or Variable index

Other Optional Features

- Angle bases for vertical axis applications

- Alternative faceplate designs

Dapra can also quote complete "turnkey" systems.

Rotary Indexing Table Specs

Two Basic Models:

Horizontal, Horizontal/Vertical (with plate)

Four Types:

Pneumatic, Pneumatic-hydraulic, Electro-pneumo-hydraulic, Electro-hydraulic

Index Drive:

Piston-rack-gear

Change of Index:

1. Fixed "F" Model – Change index pin (about 2 minutes)

2. Variable "V" Model – "Dial in" index wanted (about 5 seconds)

3. Automatic Change – Command from NC machine or indexer control

Accuracy Classes:

±24 seconds (±60 for RST1) standard

±12, ±6, ±3 or ±1 on request

Cycle Time:

Very short, below or near 1 second

Square block grinding demo

For most shop and production applications, the pneumo-hydraulic models will be sufficient. They are easy to install, easy to interlock to outside commands, and are the most economical models. A compressed air outlet (60-120 PSI) is all that is needed for hook up.

If loads, cutting pressures and forces become too great, a hydraulic model should be considered. These models can either be connected directly to the machine tool's hydraulic supply or can be supplied with their own independent power supply.

Please contact us for assistance in selecting the indexing table that will be most appropriate for your application and budget.

Coupling Options

Servopress automatic indexing tables are available with hirth gear face couplings (for higher machining forces) or ball couplings (for highest precision / wear resistance).

Accessories & Customization

There are many options available to customize the table for your application, including: angle bases for vertical applications; special seals to keep contaminants from entering the table; position interlock return signals; pneumatic tail stocks; chucks; and more. Please contact us for a solution that is customized for your particular needs.

Need help selecting the best indexer for your application?

Remember, your job is our job! We're here to help you choose and configure the correct equipment and tooling to maximize your efficiency and productivity.