Dapra offers domestically configured and assembled high-pressure vises for conventional milling machines to complex workholding solutions for flexible manufacturing centers.

Avoid deformed parts, ensure constant holding pressure and guarantee part location. Put the world's best workholding tools on the job. With Allmatic vise and tombstone systems, we hold any job just right. When you need preset holding sensitivity, close-tolerance part location or intensified holding power, only the best vise will do it all.

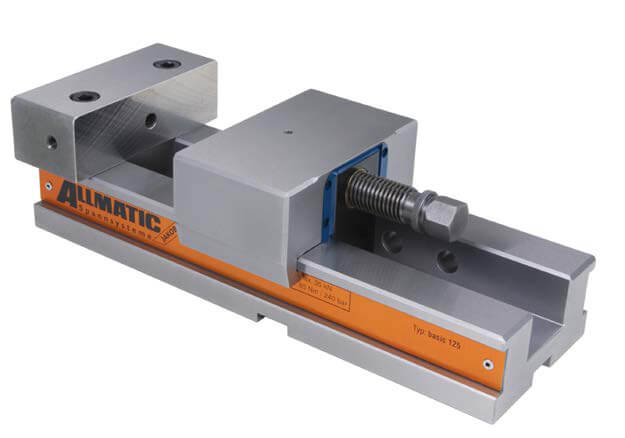

Allmatic Basic – Mechanical Vise

Simple and reliable clamping for conventional and CNC-controlled milling machines.

- Available in jaw widths of 5" (125mm) or 6.3" (160mm)

- Quick preselection of clamping range

- High clamping precision

- Innovative handling

- High variability and flexibility

- Available with hydraulic spindle or convertible later

- Maximum clamping force of 11,250 LbF (50 kN) and clamping width of 15.9" (405mm)

Allmatic HD Series

Robust design suitable for heavy machining work, single pieces and small batches.

- Clamping force preselection (2 to 4 increments) allows accurate repetition

- Tried and tested HD vice enables problem-free working with high clamping force and long-term reliability

- Available in three jaw widths: 3.9" (100mm), 5" (125mm) and 6.3" (160mm)

Allmatic NC Series

Pairing outstanding flexibility with extreme accuracy.

- Four models available: LC, TC, NC 70 and Duo 90

- Available in jaw widths from 3.9" (100mm) to 7.8" (200mm)

- Enclosed high-pressure spindle with mechanical pressure intensifier provides more than 13,000 pounds of clamping

- pressure in some models

- Variety of optional jaws available

Allmatic GRIPP Series

Six options for gripper clamping of complex unmachined parts.

- Flexible models allow for conventional clamping, gripper clamping or pull-down clamping

- Gripper studs suitable for materials with a strength of up to approx. 1000N/mm²

- T-REX is ideal for clamping unmachined parts for 5-sided machining

- TITAN SC 125 is designed for quick machining of raw parts to finished product

- Self-centering CENTRO Gripp Vise allows a workpiece to be held during the complete machining process – from start to finish

Allmatic TeleCentric Series

Five-axis vises for small- and medium-sized machine tables.

- Provides maximum accessibility

- Safe a reliable clamping; high precision and low susceptibility to vibration

- Quick-change jaws for easy changeover – for zero-point clamping systems

- Lightweight and easy to operate

- Ideal for small- and medium-sized machining tables – optimal table size: 11" to 15.75"

Allmatic Tombstones for Horizontal Machining

Multiple clamping system for horizontal machining.

- Available as single or duo version, in jaw widths of 3.5" (90mm) or 5" (125mm)

- 4 or 8 clamping stations

- Enclosed, maintenance-free, high-force spindle

- Mechanical force intensifier

- Hardened workpiece support

- Maximum clamping force of 9,000 lbf (40 kN) and clamping width of 12.3" (313mm)

Need help selecting the best vise for your application?

Remember, your job is our job! We're here to help you choose the correct equipment and tooling.