Shop by Category

Loading...

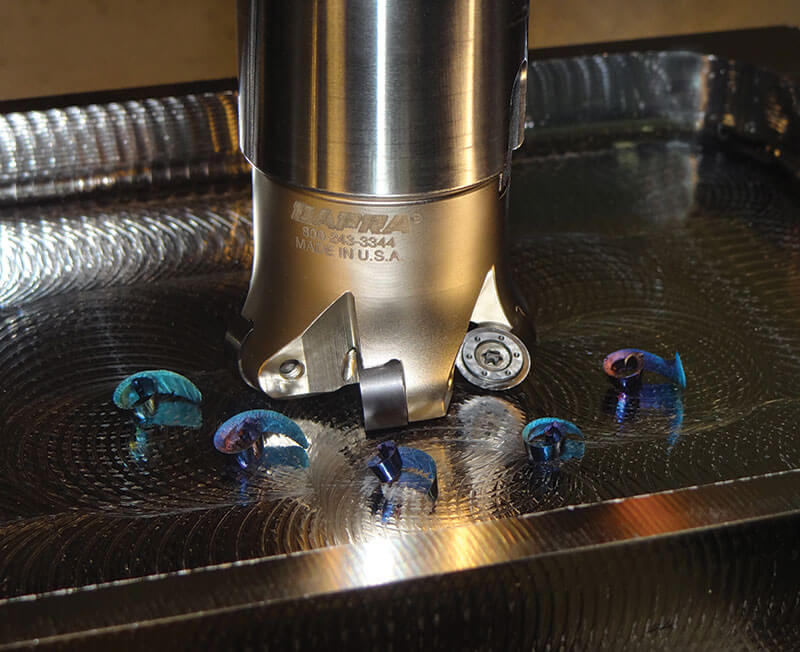

Double-Sided Button / Face Milling Reference & Troubleshooting Info

- Speed & Feed Calculator

- Recommended Operating Parameters (PDF):

» 12mm Series - Insert Loading

- Application Information

- Performance Optimization

- Feed Rate Compensation

- Hole Diameter Calculation

- Troubleshooting

- Insert Grade & Coating Selection

Need help setting up your application?

We're here to help you choose the correct tooling, inserts and operating parameters to maximize your efficiency and productivity.