Search in Category

12mm Series Inserts

Search term required.

Filter Your Search

Best For

Best For

Carbide

Carbide

Coating

Coating

Edge Type

Edge Type

Shop by Category

Loading...

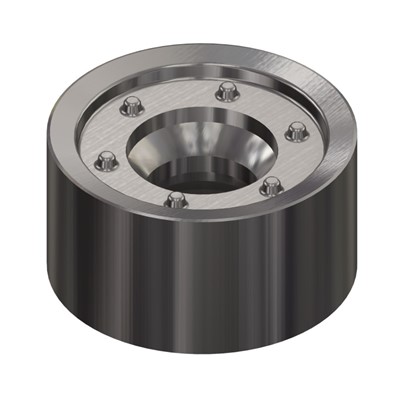

EDGE² DTB Copy Milling Series Double-Sided Button Inserts

EDGE² DTB series double-sided round button inserts have a strong cutting edge, making them an excellent choice for many applications, including:

- Mold cavity and core roughing

- Roughing of complex part contours

- Helical interpolation (larger diameter hole making)

- Pocketing

- Semifinishing

- Face milling

| Insert Part Number | IC | Thickness | # of Usable Edges | Radius | Edge Type |

|---|---|---|---|---|---|

| DTB-12-T | 12mm | .250" | 12 | 6mm | Strongest |

| DTB-12-D | 12mm | .250" | 12 | 6mm | High-Shear |

** Start with these filters – they will guide you to the right insert for your application **

Loading...

Viewing Page 1 of 2

(20 results)

| Item | Best For | Carbide | Edge Type | Coating | Grade | Price | Inventory | ||

|---|---|---|---|---|---|---|---|---|---|

|

70450 DTB-12-D-DMK30 |

ISO | 1-Toughest (Shock Resistant) | High-Shear | Uncoated | DMK30 |

In Stock

Order multiples of 10 EA |

|

||

|

70454 DTB-12-D-DMK30-HM |

ISO | 1-Toughest (Shock Resistant) | High-Shear | 1-High-temp hard | DMK30-HM |

In Stock

Order multiples of 10 EA |

|

||

|

70460 DTB-12-D-DMK30-GLH |

ISO | 1-Toughest (Shock Resistant) | High-Shear | 2-Slick High-temp | DMK30-GLH |

In Stock

Order multiples of 10 EA |

|

||

|

70480 DTB-12-D-DMK30-TCI |

ISO | 1-Toughest (Shock Resistant) | High-Shear | 4-Medium-temp | DMK30-TCI |

In Stock

Order multiples of 10 EA |

|

||

|

70485 DTB-12-D-DMK30-TS |

ISO | 1-Toughest (Shock Resistant) | High-Shear | 3-High-temp Si | DMK30-TS |

In Stock

Order multiples of 10 EA |

|

||

|

70550 DTB-12-T-DMK15 |

ISO | 3-Hardest (Wear Resistant) | Strongest | Uncoated | DMK15 |

In Stock

Order multiples of 10 EA |

|

||

|

70560 DTB-12-T-DMK15-GLH |

ISO | 3-Hardest (Wear Resistant) | Strongest | 2-Slick High-temp | DMK15-GLH |

In Stock

Order multiples of 10 EA |

|

||

|

70575 DTB-12-T-DMK15-HM |

ISO | 3-Hardest (Wear Resistant) | Strongest | 1-High-temp hard | DMK15-HM |

In Stock

Order multiples of 10 EA |

|

||

|

70580 DTB-12-T-DMK15-TCI |

ISO | 3-Hardest (Wear Resistant) | Strongest | 4-Medium-temp | DMK15-TCI |

In Stock

Order multiples of 10 EA |

|

||

|

70585 DTB-12-T-DMK15-TS |

ISO | 3-Hardest (Wear Resistant) | Strongest | 3-High-temp Si | DMK15-TS |

In Stock

Order multiples of 10 EA |

|

70450

DTB-12-D-DMK30

- ISO

- 1-Toughest (Shock Resistant)

- High-Shear

- Uncoated

- DMK30

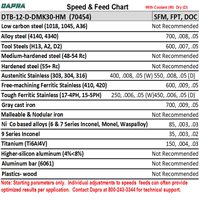

70454

DTB-12-D-DMK30-HM

- ISO

- 1-Toughest (Shock Resistant)

- High-Shear

- 1-High-temp hard

- DMK30-HM

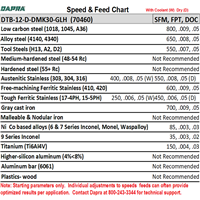

70460

DTB-12-D-DMK30-GLH

- ISO

- 1-Toughest (Shock Resistant)

- High-Shear

- 2-Slick High-temp

- DMK30-GLH

70480

DTB-12-D-DMK30-TCI

- ISO

- 1-Toughest (Shock Resistant)

- High-Shear

- 4-Medium-temp

- DMK30-TCI

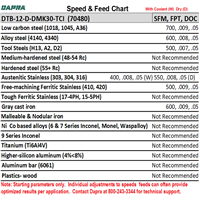

70485

DTB-12-D-DMK30-TS

- ISO

- 1-Toughest (Shock Resistant)

- High-Shear

- 3-High-temp Si

- DMK30-TS

70550

DTB-12-T-DMK15

- ISO

- 3-Hardest (Wear Resistant)

- Strongest

- Uncoated

- DMK15

70560

DTB-12-T-DMK15-GLH

- ISO

- 3-Hardest (Wear Resistant)

- Strongest

- 2-Slick High-temp

- DMK15-GLH

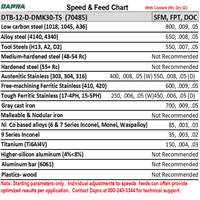

70575

DTB-12-T-DMK15-HM

- ISO

- 3-Hardest (Wear Resistant)

- Strongest

- 1-High-temp hard

- DMK15-HM

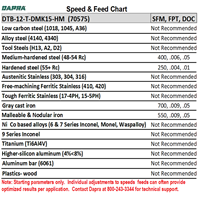

70580

DTB-12-T-DMK15-TCI

- ISO

- 3-Hardest (Wear Resistant)

- Strongest

- 4-Medium-temp

- DMK15-TCI

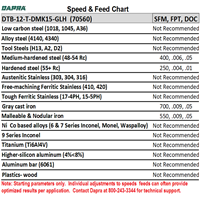

70585

DTB-12-T-DMK15-TS

- ISO

- 3-Hardest (Wear Resistant)

- Strongest

- 3-High-temp Si

- DMK15-TS