Shop by Category

Loading...

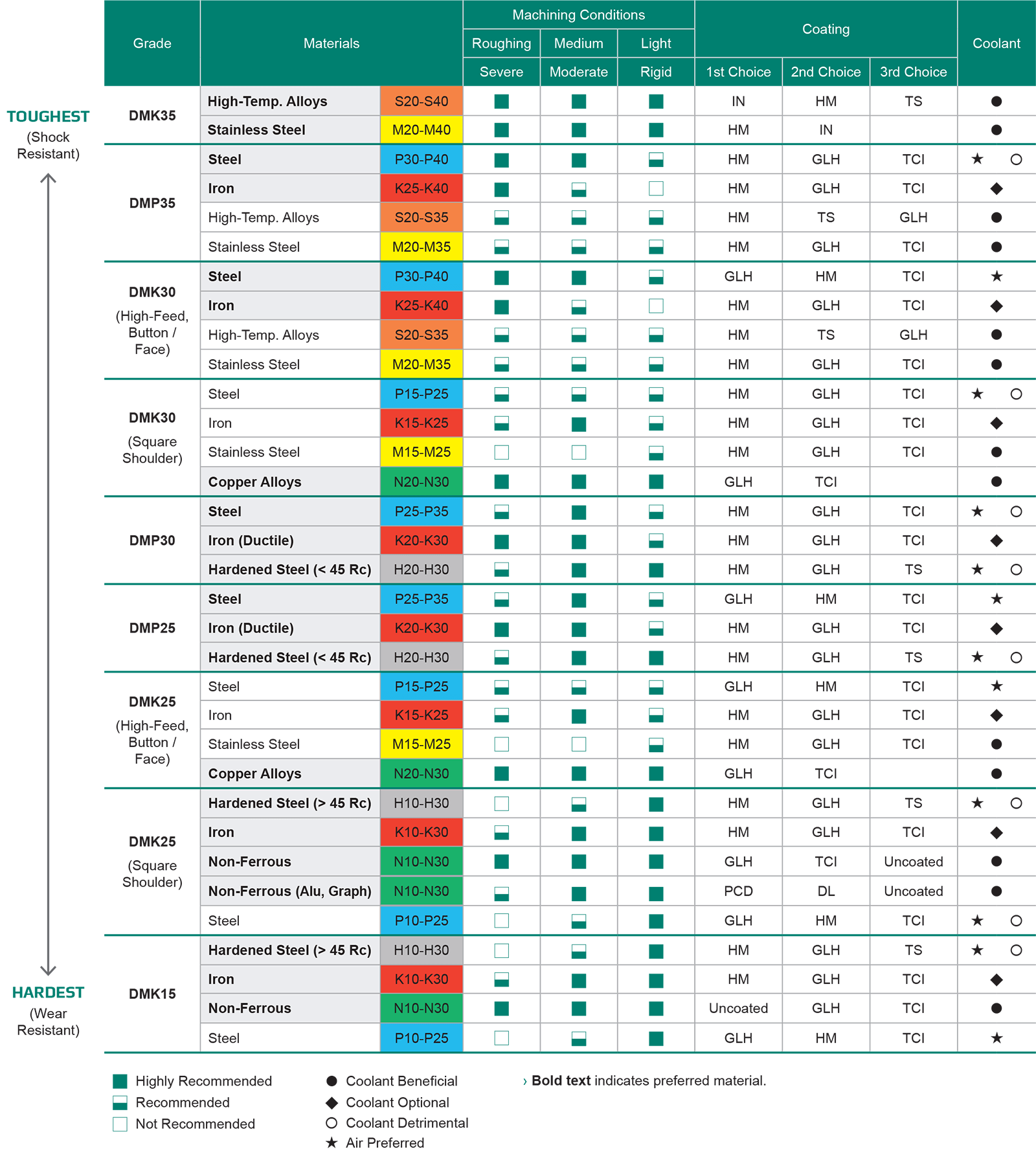

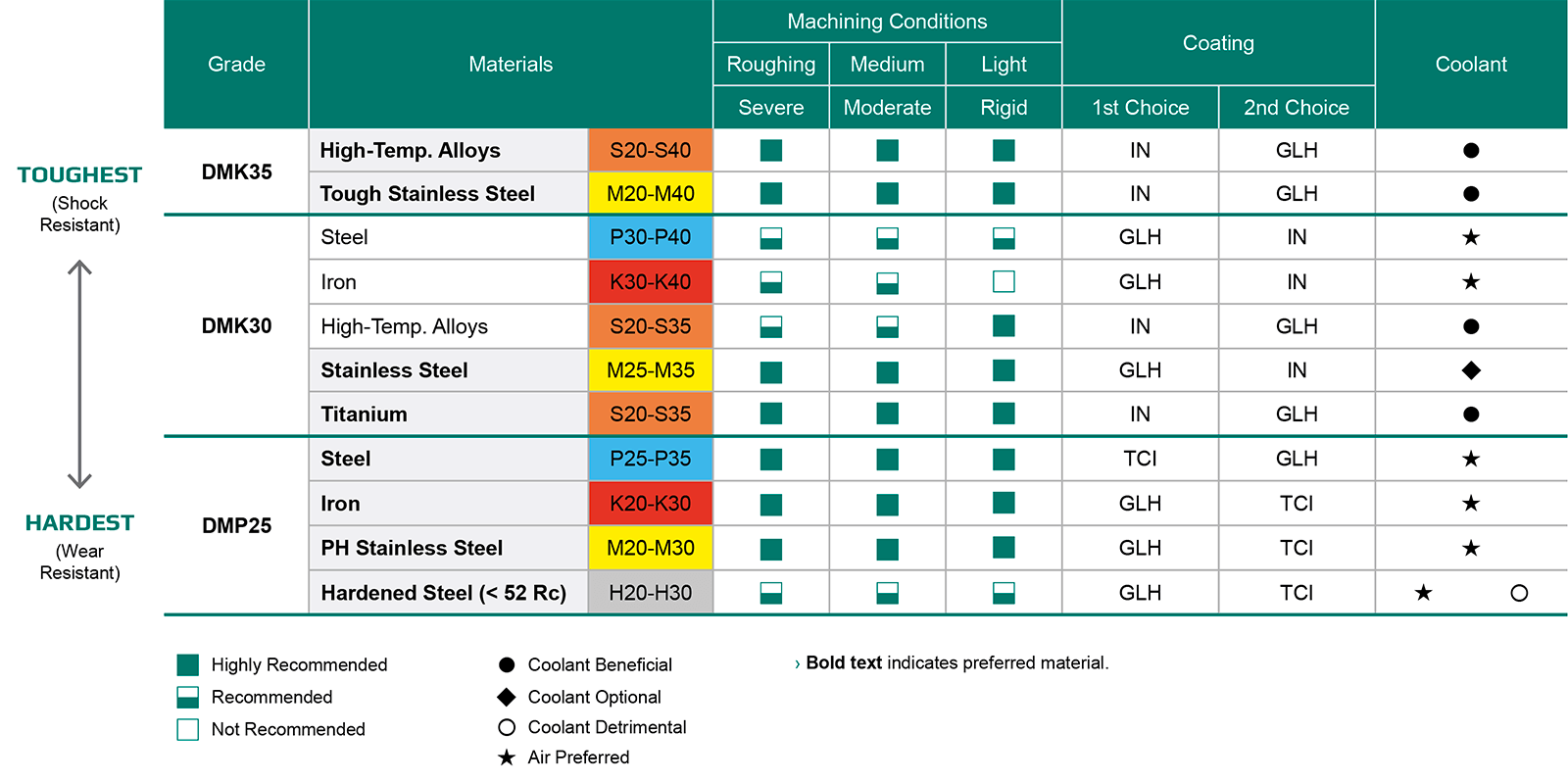

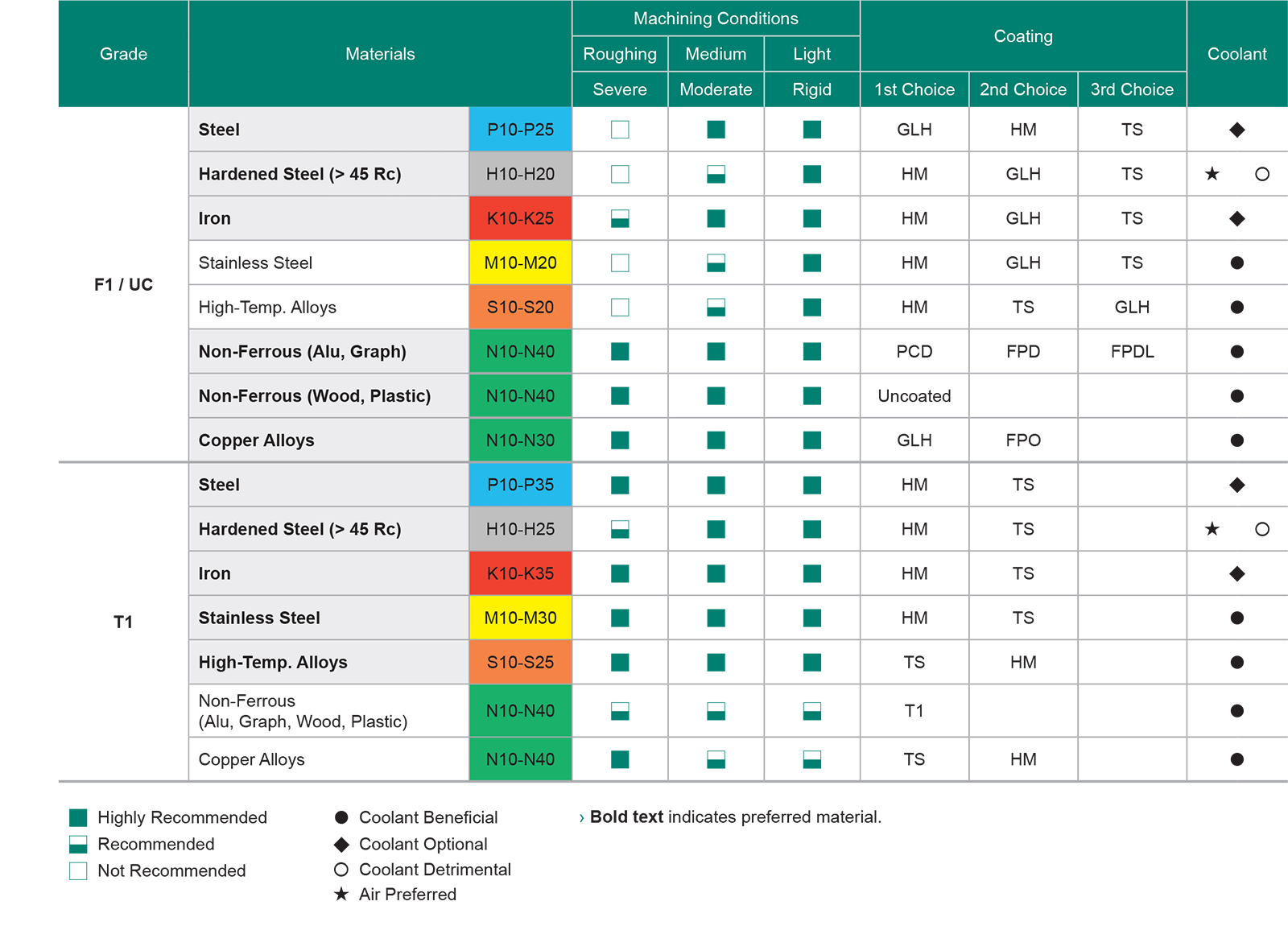

Milling Insert Grade & Coating Selection

High-Feed, Square Shoulder, & Button / Face Inserts

Need help with insert selection?

We're here to help you choose the correct tooling, inserts and operating parameters to maximize your efficiency and productivity.